Gate with FIVE LEGGED SEAT STRUCTURE

Gate with FIVE LEGGED SEAT STRUCTURE

THIS was a 3-weekend workshop <6 days> in Jay's shop in July 2005. The participants were Brian Beck, Holden Crane, Stella Breslin, Hernan Hsu and Pat Sawanwatana. Brian is a recent grad of Arques boat school apprenticeship and is now at the College of the Redwoods in Ft. Bragg, Ca. Holden is also a recent grad of Arques is a NorthBay builder and boat builder. Stella is a student from Jay's shop classes in the 90"s and is still at it. Herman is a regular daiku dojo member who has worked with Jay and a Laney woodtech grad who is a furniture designer maker living and working in the Bay Area. Pat is an avid supporter of DaikuDojo and is the owner of the best country Thai restaurant -Old Weang Ping Village- in the Bay area and beyond.

We started this workshop with some basic ideas about the structure we wanted to build. we did not start with a

finished idea of what was going to happen or how it would come out. We wanted to have room to come up with some

tastey details and use our tools and techniques to carry out our project. The carved side beams with the painted

edge were used from the gate structure we built last year (picts available elsewhere on this site) and set the

size and proportions for this structure. Solving problems and coming up with a plan is an important part of this

kind of learning situation - not just learning to follow plans worked up by others..., and of course, using our

tools to the fullest extent we can, is always our goal and pleasure.

|

1> Holden, Stella, and Jay talking and planning about how the structure can go together- unassembled pieces on the work table in Jay's shop. Communication is very inportant when building a group project. |

|

2>Posts-3-4x4 Port Orford cedar and a modified 6x6 doug Fir (adzed with a chona and yariganna) with bridle joints cut and bottom ends carved to fit foundation stones laying on sawhorses. |

|

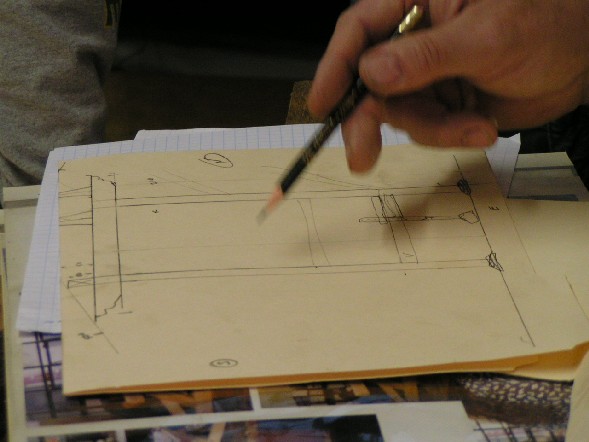

3>going over preliminary elevations. |

|

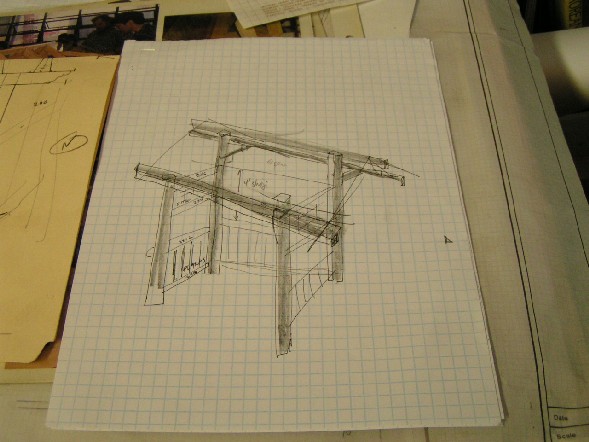

4>Preliminary shop sketch of structure gives ideas, sizes, proportions for the direction we want to go. |

|

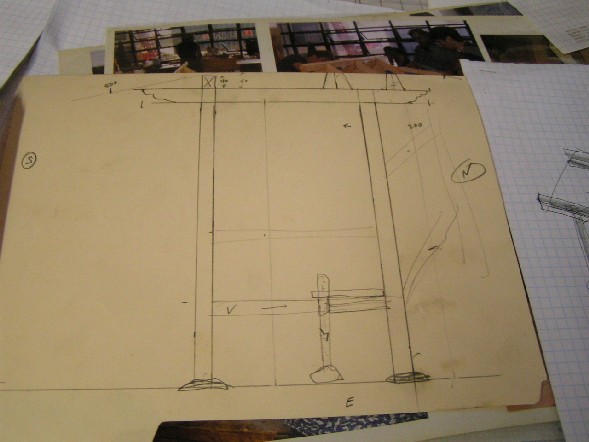

5>elevation showing posts on rocks, cross beams |

|

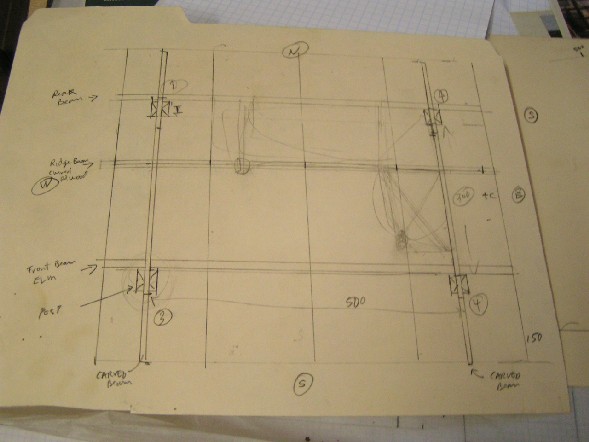

6>plan view of preliminary sketch showing posts, beams and rafter placements. |

|

7>Brian, Jay, Stella, and Holden assessing progress of roof beams and joinery construction. |

|

8>Brian, Jay,Stella and Pat adjusting the rear beam and its bridle joint fits. |

|

9>Stella and Pat watching progress: Holden checking out a 330 mm ryoba. |

|

10>Brian peeling the bark off a redwood log used for the 5th Leg. |

|

11>structure being assembled outside of the shop |

|

12>another shot of assembly |

|

13>Holden using a curved bottom plane finishing the adzed post-stone base on the far end and bridle with 2 tenons near end. |

|

14>Holden working on adzed post. Brian laying out the 5th leg with log and housed sliding dove-tail tenon with keyed splicing joint. |

|

15>Stella cleaning up a mortise for the 45° seat brace. |

|

16>Holden and Brian planing and sawing |

|

17>Stella doing a layout |

|

18>Holden, Jay and Stella fitting rear rafters |

|

19>talking about rafter assembly - curved ridge beam and front beam give a rolling effect for the roof rafters. |

|

20>talking and figuring out a solution |

|

21>Jay getting ready to position a curbed elm plank for the seat on the structure frame |

|

22>view of seat part of structure with curved seat planks |

|

23>front view of seat planks |

|

24>front view of seat planks |

|

25>Brian and Holden refining their polishing using a variety of natural TOISHI. Brian examines his edge with a microscope = "shiny doesn't necessarily mean it's sharp!" |

|

26>Stella getting her groove back, and checking out the results. |

|

27>structure partially assembled with some boards on the roof to start to see the compound cuvres in the roof lines |

|

28>structure from the other side |

|

29>underneath shot of posts, beams, and rafters: -note:bridle joints secured by tapered wedges to hold joint together by increasing the compression on the endgrain of the mortises--this helps when the joints will be taken apart a number of times to be worked on or moved. |

|

30>shot of posts and seat structure with elm plank to be joined into a continous seat. |

|

31>5th leg with keys in splice joint with sliding dovetail tenon. |

|

32>right rear post with beams and rafters-all connections are bridle and typical connections using 2x6 stock - wrong sizes for mortise and tenon joints |

|

33>left side |

|

34>front elm beam from below showing rafters and temporary roof planks |

|

35>adzed post on stone with 5th leg, redwoodpost on stone base and keyed sliding dovetail tenon splicing joint. |